10 Simple Techniques For High Temperature Hazloc Heating Cable

Table of ContentsSelf-regulating Heating Cable Fundamentals ExplainedSelf-regulating Heating Cable - TruthsThe Basic Principles Of Heat Trace

The Institute of Electrical and Electronics Engineers Incorporated Sector Applications Society 44th Yearly Magazine Year: 1997, 215223. Cited by: Documents (1) N.R. Rafferty and also G - Self-Regulating Heating Cable. Tarbutton. "IEEE 844-2000: Advised Practice for Electric Insusceptibility, Induction, and also Skin Impact Heating of Pipelines as well as Vessels," IEEE Purchases on Sector Applications 38, no. 4 (2002 ): 921-926.

View Delta-Therm Corporation in a full screen map

Richard Huff and Chet Sandberg, "Design, Appointing and also Operational Experience of a Heat Tracing System with Comprehensive Electronic Tracking" IEEE Transactions on Industry Applications 26, no. 6 (November/December 1990): 1070-1074. C. J. Erickson, N. R. Rafferty, J. D. Lyons, and C. L. Sandberg, "A Research of Steam vs. Electrical Pipeline Heating Costs on a Normal Petro-Chemical Plant Task," IEEE PCIC Meeting, Houston Texas, September 1990, PCIC-90-2.

By Steven Bench I obtained a phone call this early morning from a potential consumer desiring tounderstand the difference in between Warm Trace, Warmth Tape, as well as GutterMelt. Afterexplaining the differences to him it took place to me that maybe others are confused so Idecided to compose this write-up. Warm Trace and also Warm Tape are common terms for a household of electrical home heating cable televisions thatare designed to keep pipelines from cold, maintain the temperature level of the components ofpipes and thaw snow and also ice off of roofings and in drains pipes, rain gutters and also downspouts.

Undoubtedly the Heat Trace and also Heat Tape products designed for gutter, downspoutsand on roof coverings are developed to be revealed to the components including the rays from the sun. Heat Trace. Within the household of electrical home heating cables described as "Warmth Trace" or "Warm Tape"are Continuous Power level cords as well as Self Managing cords.

The wattage outputper straight foot of Self Managing cables on the other hand, varies drastically as thetemperature bordering the cable changes. As a matter of reality the wattage result of alength of Self Controling cable television may differ as the temperature bordering the cord variesalong its size. The numerous brands of Constant Electrical power Warmth Trace or Warmth Tape wires are available in manydifferent quality degrees as well as price points as well as are generally taken care of in length.

Some Known Facts About Heat Trace.

Within the Continuous Power level section of Warmth Trace or Warmth Tape, rates rangefrom much less than a dollar to several bucks per foot, and life expectancy varies from a yearor 2 to 10 or more years. The power level result of Constant Electrical power cords varies from afew watts per foot as much as 50 plus watts per foot.

LikeConstant Electrical power cable televisions, the top quality and also price of Self Controling Heat Trace or Heatis determined by the layout long life, temperature level resistance, and also electrical power result. Thesecables normally have wattage outcomes varying from 3 to 24 plus watts per foot in acertain medium (air, ice, water, etc.) as well as at a particular temperature level.

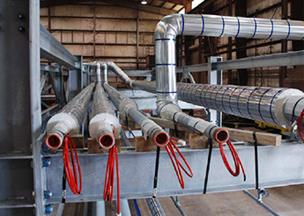

Heat-tracing systems can be separated right into two wide courses, electrical and fluid. Fluid heat-tracing systems utilize heating media at elevated temperatures to transfer warm to a pipeline. The liquid is normally had in a tube or a small pipeline connected to the pipe being mapped. If steam is the mapping fluid, the condensate is either went back to the boiler or unloaded. Various other specialized electric tracing systems make use of resistance, induction, and also skin transmission results to create and transfer heat. Heavy steam mapping is the application of vapor warm to piping Commercial/industrial Self-Regulating Cable as well as vessels for the function of preserving wanted process temperatures, freeze protection, viscosity control or to get a temperature level control factor within a liquid for its chemical communication in a process.

The entire setting up is then insulated to route the warm into the procedure fluid. Numerous technical short articles have been created worrying heavy steam mapping in addition to their connected heat loss equations and charts. Self-Regulating Commercial/industrial Self-Regulating Cable Heating Cable. Younger engineers, upkeep employees, pipeline fitters as well as others that heavy steam trace do not always make use of efficient methods for winterization and also procedure temperature upkeep.

When a product in a pipeline goes to a greater temperature than the air bordering it, warm will pass through the wall of the pipe from the item to the surrounding air. This warmth loss will certainly cause the temperature of the product to drop. Shielding the pipeline will considerably lower the rate at which heat is shed, however unfortunately, no insulation is 100% effective.

The Main Principles Of Self-regulating Heating Cable

It can transfer warmth over cross countries as well as quits its warmth at a continuous temperature level. To make up Heat Trace the warm shed from the item pipe, small bore heavy steam pipes, or tracers, are affixed to the product line. Warm from the vapor enters the product as well as replaces the warmth lost.

The very same kind of control can additionally be used in winterization applications, just allowing steam right into the tracing line when the ambient temperature drops listed below a fixed level. Jacketed - used in ultra-critical applications, normally where a product temperature level needs to be kept at an elevated temperature level all of the time.

Crucial - right here, steam tracing is made use of to preserve the temperature level of a product that will certainly strengthen or spoil should its temperature level fall below an established level. Non-critical - tracing is utilized to keep the item viscosity at its maximum pumping degree. Winterization - to make certain pipelines are not damaged because of cold in adverse climate condition.

To choose the dimension and also number of vapor mapping lines needed for a certain application, the rate of warm loss from the product pipeline under worst layout conditions need to be established. This price of warm loss is dependant upon the distinction in between the product temperature level and the ambient temperature. Various other variables such as the thermal conductivity of the insulation, ambient wind rate and the emissivity of the insulation surface will impact this rate of loss.